Plastic Parts / Injection Moulding

Injection moulding is well established in China. Our plastic parts and enclosures are highly competitive in terms of quality and price. Additionally, you can save a lot of money on the moulds.

Soon after we started assembling electronics, our customers also needed highly competitive plastic parts and enclosures. Making use of our splendid supply chain, we can save a lot of money on your moulds, plastic parts and printing services. Depending on the application, we apply PVC, PE and ABS to achieve the best results in terms of quality and price. Most of the plastic parts will be painted after which logo’s and further details are printed or silk screened.

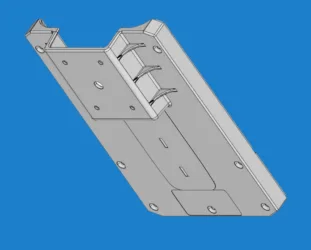

For prototyping, we often gain time and money, by printing the plastic parts, before making the moulds. Checking fit, form, function well in advance of mass production can save you lots of trouble.

3D printed bracket

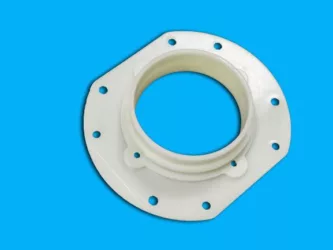

Injection Molding

Cradle

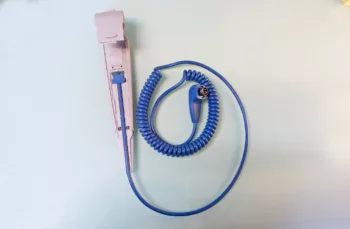

High end Trolleys

Grips